Styrofoam, a ubiquitous material known for its lightweight nature and excellent insulating properties, is widely used in various applications. However, understanding its thermal behavior is crucial for safe handling and effective utilization. This article delves into the softening temperature of Styrofoam, exploring its heat resistance, the effects of high temperatures, and best practices for storage and application.

This comprehensive guide will cover the specific temperature at which Styrofoam begins to soften, examine its overall heat resistance capabilities, and discuss the consequences of exposing it to elevated temperatures. We’ll also outline safe handling and storage procedures and highlight applications where Styrofoam’s heat resistance is essential.

Styrofoam Softening Temperature

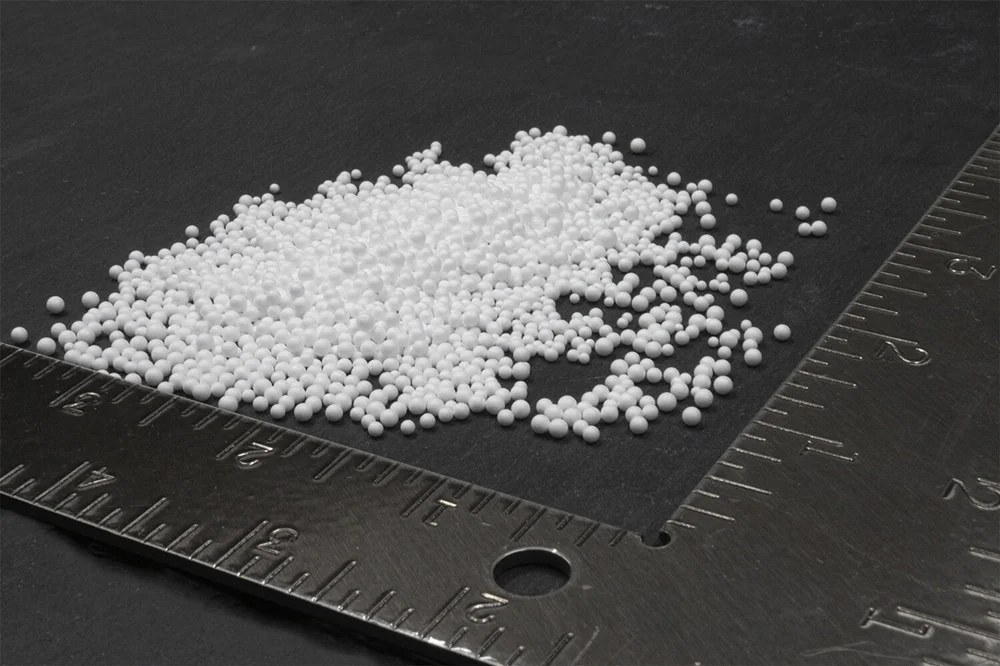

Styrofoam, a type of expanded polystyrene (EPS), starts to soften and lose its structural integrity around at what temperature does styrofoam melt? 170°F (77°C). It’s important to note that Styrofoam doesn’t technically “melt” in the traditional sense. Instead, it undergoes a process of softening and deformation when exposed to temperatures above this threshold. Prolonged exposure to higher temperatures will cause further softening, eventually leading to breakdown and disintegration.

The softening temperature of Styrofoam can vary slightly depending on factors such as the density and formulation of the material. However, 170°F (77°C) serves as a general guideline for understanding its thermal behavior.

Heat Resistance of Styrofoam

While Styrofoam exhibits good insulation properties, it’s not inherently highly heat-resistant. Its softening point indicates that it’s susceptible to deformation and damage at relatively moderate temperatures compared to other materials like metals or ceramics.

Styrofoam’s primary function lies in its ability to trap air within its cellular structure, creating an insulating barrier against heat transfer. This makes it effective for applications where maintaining a specific temperature is crucial, such as food packaging and insulation in buildings. However, it’s not suitable for environments with prolonged exposure to high temperatures.

Effects of High Temperatures on Styrofoam

Exposing Styrofoam to temperatures exceeding its softening point can have several detrimental effects:

- Deformation: The material will soften and lose its shape, becoming pliable and susceptible to bending or warping.

- Brittleness: As the temperature increases further, Styrofoam can become brittle and prone to cracking or shattering.

- Disintegration: Prolonged exposure to high temperatures will eventually cause Styrofoam to break down into smaller pieces, reducing its structural integrity and effectiveness as an insulator.

Safe Handling and Storage of Styrofoam

To ensure the safe handling and storage of Styrofoam, consider these guidelines:

- Avoid direct heat sources: Keep Styrofoam away from open flames, heating elements, and other sources of intense heat.

- Store in a cool, dry location: Protect Styrofoam from extreme temperatures and moisture, which can accelerate its degradation.

- Handle with care: Avoid dropping or mishandling Styrofoam to prevent damage and deformation.

Applications Requiring Heat Resistance

While Styrofoam’s heat resistance is limited, it finds applications where moderate temperature control is sufficient:

- Food packaging: Styrofoam containers are commonly used for takeout food due to their insulating properties, keeping food warm for a period of time.

- Building insulation: Styrofoam panels are used in walls and roofs to provide thermal insulation, reducing heat transfer between the interior and exterior of buildings.

- Shipping protection: Styrofoam peanuts and blocks are used as cushioning material in packaging to protect fragile items during transportation.

Conclusion

Understanding the softening temperature of Styrofoam is crucial for its safe and effective use. While it offers excellent insulating properties, it’s not highly heat-resistant and can soften and degrade at relatively moderate temperatures. By adhering to proper handling and storage guidelines and considering its limitations in high-temperature applications, you can maximize the benefits of this versatile material.