Lubrication is essential for smooth operation and longevity of machinery. Two common lubricants, oil and grease, play crucial roles in various applications. While both reduce friction and wear, their distinct properties make them suitable for different purposes. Understanding these differences is key to selecting the right lubricant for optimal performance and equipment lifespan.

This article delves into the world of lubrication, exploring the difference between grease and oil, examining various types of lubricants, and outlining their specific applications. By the end, you’ll have a comprehensive understanding of how to choose the best lubricant for your needs, ensuring efficient and reliable operation of your machinery.

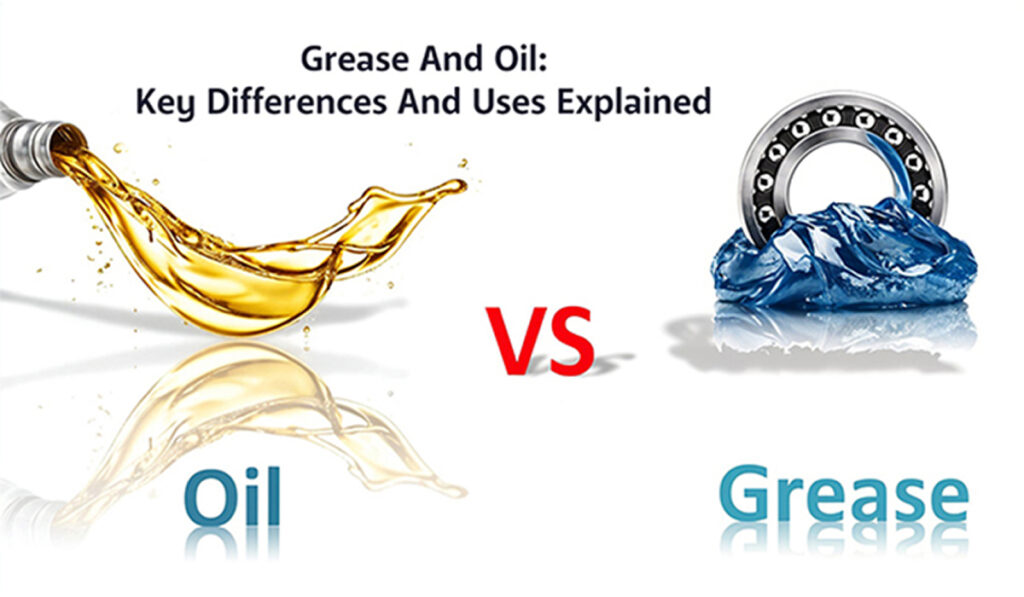

Oil vs Grease

The fundamental difference between grease and oil lies in their physical state and composition. Oil is a liquid at room temperature, composed primarily of hydrocarbons. Its fluidity allows it to flow easily, effectively lubricating moving parts and dissipating heat generated during operation. Grease, conversely, is a semi-solid mixture of oil and thickening agents like soap or clay. This thickened consistency provides long-lasting lubrication in low-speed applications and environments where oil might leak or evaporate.

Another key distinction is their application. Oil excels in high-speed machinery due to its ability to flow quickly and efficiently between moving parts, minimizing friction and heat buildup. Grease, on the other hand, is ideal for low-speed applications like bearings, gears, and hinges, where a thicker lubricant can effectively seal out contaminants and provide long-term protection.

Types of Lubricants

Both oil and grease come in various formulations tailored to specific applications.

Oil Types:

- Mineral Oil: Derived from petroleum, mineral oil is widely used due to its affordability and versatility. It’s suitable for a range of applications, including engines, gearboxes, and hydraulic systems.

- Synthetic Oil: Engineered from chemically synthesized compounds, synthetic oil offers superior performance compared to mineral oil. It boasts higher viscosity index, meaning it maintains its lubricating properties over a wider temperature range. Synthetic oils are often used in high-performance engines and demanding industrial applications.

Grease Types:

- Lithium Grease: A common type of grease, lithium grease is known for its excellent water resistance and stability at moderate temperatures. It’s widely used in automotive and industrial applications.

- Calcium Grease: Calcium grease offers good lubrication properties at low temperatures but is less resistant to water than lithium grease. It’s often used in agricultural equipment and other applications where exposure to moisture is minimal.

Applications of Oil

Oil finds widespread use in various industries due to its fluidity and ability to dissipate heat.

- Automotive: Engine oil lubricates moving parts within the engine, reducing friction and wear. Transmission fluid ensures smooth gear shifting and protects internal components.

- Industrial Machinery: Hydraulic oils power hydraulic systems, providing force for lifting, pressing, and other operations. Gear oils lubricate gears in machinery, minimizing noise and extending lifespan.

Applications of Grease

Grease’s thick consistency makes it ideal for low-speed applications where long-lasting lubrication is required.

- Bearings: Grease effectively seals out contaminants and provides continuous lubrication to bearings, reducing friction and wear.

- Gears: Grease lubricates gears in machinery, minimizing noise and extending gear life. It also helps prevent corrosion and rust formation.

- Hinges: Grease lubricates hinges on doors, gates, and other moving parts, ensuring smooth operation and preventing sticking.

Choosing the Right Lubricant

Selecting the appropriate lubricant depends on several factors:

- Operating Temperature: Different lubricants perform optimally within specific temperature ranges. Choose a lubricant suitable for the expected operating conditions.

- Speed: High-speed applications require fluid lubricants like oil, while low-speed applications benefit from thicker greases.

- Environmental Conditions: Consider factors like humidity, dust, and exposure to chemicals when choosing a lubricant. Some lubricants offer better resistance to environmental factors than others.

Always consult the manufacturer’s recommendations for specific equipment and refer to lubrication charts for guidance on selecting the right lubricant based on application and operating conditions.

Conclusion

Understanding the difference between grease and oil is crucial for effective machinery maintenance and optimal performance. By considering factors like operating temperature, speed, and environmental conditions, you can choose the right lubricant for your specific needs. Remember to consult manufacturer recommendations and lubrication charts for guidance. Proper lubrication ensures smooth operation, reduces wear and tear, extends equipment lifespan, and ultimately contributes to efficient and reliable performance.