Stop signs are ubiquitous symbols of road safety, guiding drivers to halt their vehicles and yield to oncoming traffic or pedestrians. But have you ever stopped to consider the weight of these seemingly simple traffic control devices? Understanding the weight of a stop sign is more than just a trivia question; it plays a crucial role in ensuring safe and efficient traffic flow.

This article delves into the factors influencing how much does a stop sign weigh, exploring the materials used, the importance of its weight for both safety and infrastructure planning, and the considerations surrounding mounting hardware. By shedding light on these aspects, we aim to provide a comprehensive understanding of the significance of stop sign weight.

Stop Sign Weight

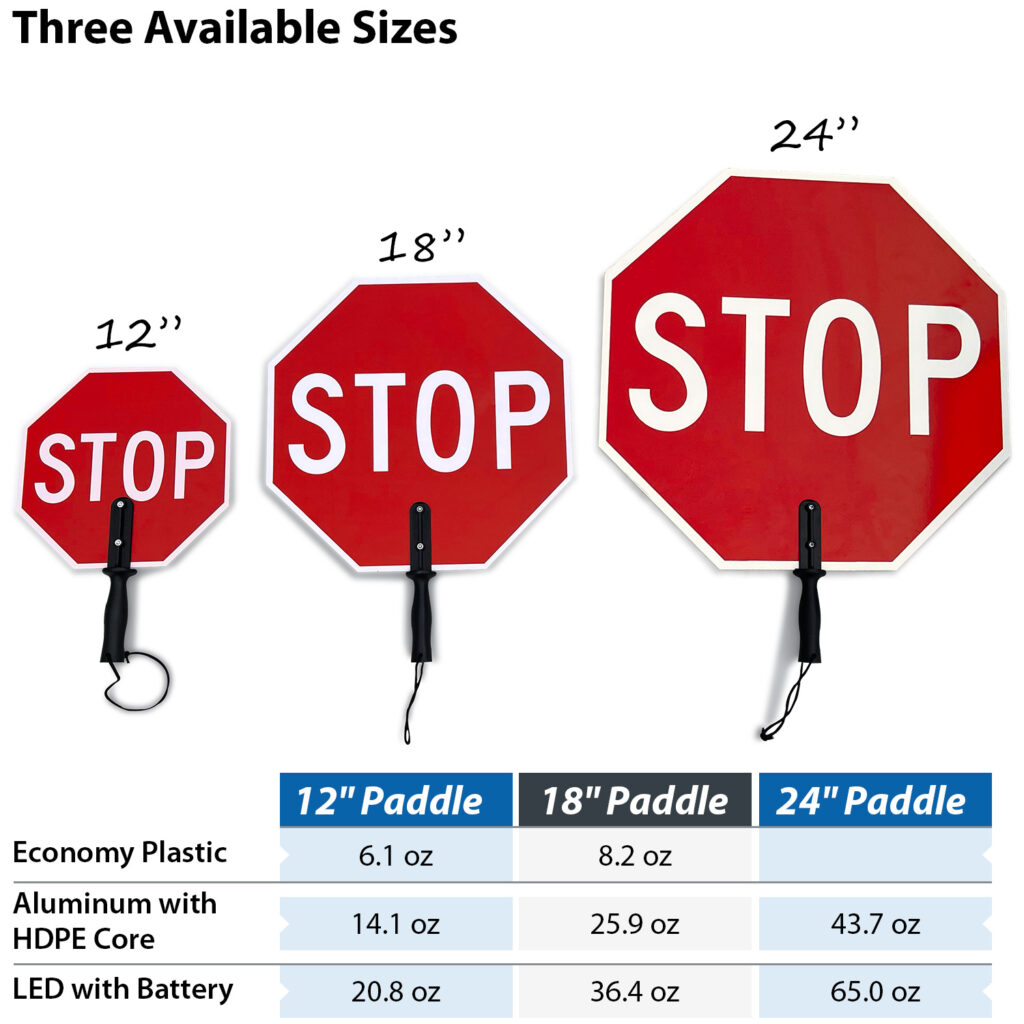

The weight of a standard stop sign typically falls within the range of 1 to 2 pounds. This relatively lightweight design is intentional, as it facilitates easy installation and handling during maintenance procedures. Factors influencing the exact weight include the specific materials used in its construction and the size of the sign itself.

While aluminum remains a popular choice for its durability and corrosion resistance, some stop signs are manufactured using plastic materials like polyethylene or polypropylene. These alternatives often result in lighter-weight signs, contributing to reduced installation costs and environmental impact. The dimensions of the stop sign also play a role; larger signs naturally weigh more than their smaller counterparts.

Materials Used in Stop Signs

Stop signs are primarily constructed from two main materials: aluminum and plastic. Each material possesses distinct properties that influence both the weight and performance of the sign. Aluminum, known for its strength, durability, and resistance to corrosion, has long been a favored choice for stop sign manufacturing. Its lightweight nature further contributes to its popularity.

Plastic materials, such as polyethylene or polypropylene, have emerged as viable alternatives to aluminum. These plastics offer comparable durability and weather resistance while often resulting in lighter-weight signs. The selection of material depends on factors like cost, environmental considerations, and the specific requirements of the location where the stop sign will be installed.

Importance of Stop Sign Weight

The weight of a stop sign may seem insignificant at first glance, but it plays a crucial role in ensuring both traffic safety and the longevity of the sign itself. An appropriately weighted stop sign can withstand wind gusts and other environmental factors without becoming dislodged or damaged.

A lightweight stop sign that is too flimsy could easily be blown over by strong winds, posing a hazard to motorists and pedestrians alike. Conversely, an excessively heavy stop sign might require more robust mounting hardware, increasing installation costs and potentially straining the supporting structure. Therefore, finding the optimal weight balance is essential for maintaining safe and efficient traffic flow.

Mounting Hardware Considerations

The weight of a stop sign directly influences the type of mounting hardware required to secure it effectively. Lighter-weight signs can often be mounted using simpler brackets or pole attachments, while heavier signs may necessitate more robust hardware such as heavy-duty bolts, anchors, and specialized mounting systems.

Engineers and traffic safety professionals carefully consider the weight of the stop sign in conjunction with factors like wind load, traffic volume, and the surrounding environment when selecting appropriate mounting hardware. Properly installed mounting hardware ensures that the stop sign remains securely in place, even under challenging weather conditions or heavy traffic flow.

Traffic Safety and Infrastructure Planning

Understanding how much does a stop sign weigh is integral to effective traffic safety and infrastructure planning. When designing roadways and intersections, engineers must account for the weight of traffic control devices like stop signs to ensure their stability and effectiveness.

This consideration extends beyond individual stop signs to encompass the overall weight distribution of traffic control elements within an intersection. By carefully calculating the weight of all signage, pavement markings, and other infrastructure components, engineers can create safer and more efficient traffic flow patterns.

Conclusion

The seemingly simple question of how much does a stop sign weigh holds significant implications for road safety, infrastructure planning, and even environmental considerations. From the materials used to the mounting hardware required, every aspect of a stop sign’s design is influenced by its weight.

By understanding the factors that determine stop sign weight and their impact on traffic flow and safety, we can contribute to creating safer and more efficient roadways for everyone.