Propane is a versatile fuel source used in various applications, from powering grills and heating systems to fueling vehicles. A key aspect of safe propane handling involves understanding the unique threading system employed on propane tanks. Unlike standard threaded containers that tighten clockwise, propane tanks utilize a reverse thread design. This counterclockwise tightening mechanism plays a vital role in ensuring a secure and leak-proof connection when attaching the tank to appliances or regulators.

This article will delve into the intricacies of propane tank reverse threading, providing you with a comprehensive understanding of its purpose, safety precautions, and practical applications. We’ll explore the benefits of this design, guide you through the process of using a propane regulator with reverse threads, and ultimately empower you to handle propane safely and efficiently.

Propane Tank Reverse Threading Explained

The reverse threading on propane tanks refers to the direction in which the valve connection needs to be tightened. Instead of turning clockwise like most threaded connections, propane tank valves are tightened by turning counterclockwise. This seemingly simple difference has significant implications for safety and functionality.

The reason behind this unique design lies in the inherent pressure within propane tanks. When a propane tank is connected to an appliance or regulator, the valve must create a tight seal to prevent leaks. Reverse threading helps achieve this by ensuring that the threads are pulled together firmly when tightened counterclockwise. This creates a more secure connection and reduces the risk of leaks, which can be hazardous due to the flammability of propane.

Understanding this reverse threading is crucial for anyone working with propane tanks. Incorrect tightening can lead to loose connections, potential gas leaks, and even explosions. Always double-check the direction of rotation before tightening any propane tank valve connection.

Safety Precautions for Reverse Threading

When handling propane tanks, safety should always be your top priority. The reverse threading system, while designed for enhanced security, requires extra vigilance to prevent accidents.

Always inspect the valve connection before and after use. Look for signs of damage, wear, or loose connections. If you notice any issues, do not attempt to use the tank. Contact a qualified propane technician for inspection and repair.

* Never overtighten the valve connection. Excessive force can strip the threads or damage the valve, leading to leaks. Tighten the connection firmly but avoid excessive turning.

- Use appropriate tools. A wrench designed specifically for propane tanks is recommended. Avoid using improvised tools that could damage the valve or create a dangerous situation.

- Work in a well-ventilated area. Propane gas is flammable and can accumulate in enclosed spaces. Ensure adequate ventilation when handling propane tanks.

Benefits of Reverse Thread Design

The reverse threading system employed on propane tanks offers several advantages over traditional threaded connections:

- Enhanced Security: The counterclockwise tightening mechanism creates a more secure seal, reducing the risk of leaks and ensuring a reliable connection between the tank and appliances or regulators.

Leak Prevention: Reverse threading helps prevent accidental loosening of the valve connection due to vibrations or movement. This is particularly important in applications where propane tanks are subjected to frequent handling or transportation.

Standardization: The widespread adoption of reverse threading on propane tanks promotes standardization within the industry, simplifying connections and ensuring compatibility between different brands and models.

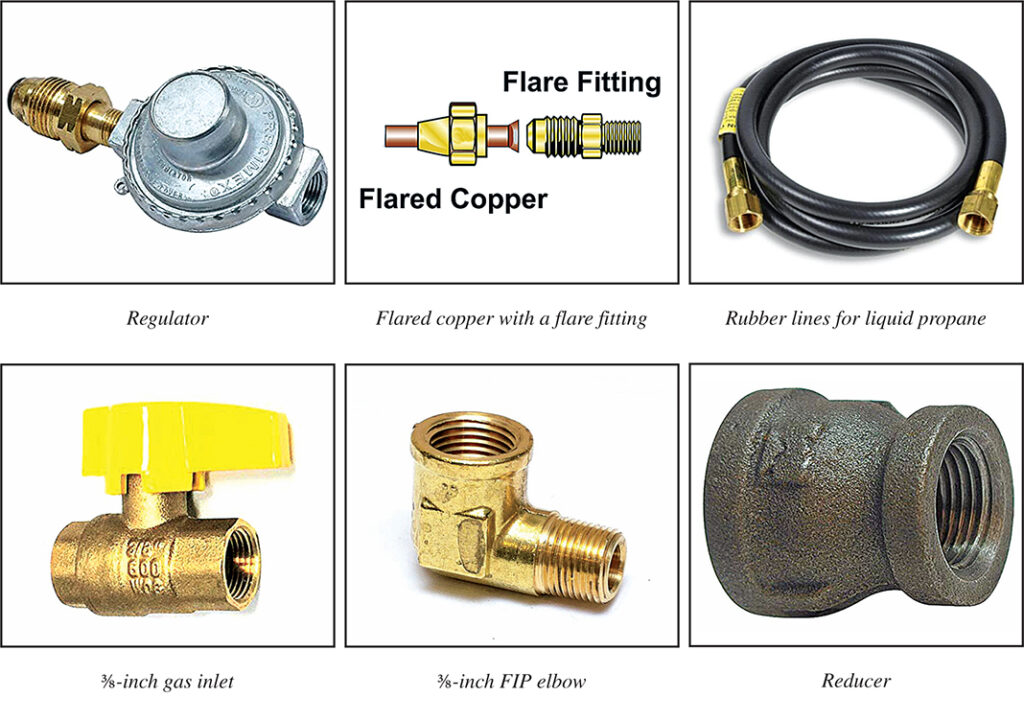

Using a Propane Regulator with Reverse Threads

Propane regulators play a crucial role in controlling the flow of propane from the tank to appliances. When using a regulator with a propane tank featuring reverse threads, follow these steps:

- Identify the Thread Type: Ensure that your regulator is compatible with the reverse thread design of the propane tank. Check the manufacturer’s specifications or consult a propane technician if you are unsure.

- Connect the Regulator: Align the regulator connection with the valve outlet on the propane tank.

Tighten Counterclockwise: Turn the regulator clockwise to tighten the connection securely. Remember, propane tanks utilize reverse threading, so turn counterclockwise to loosen and clockwise to tighten.

Check for Leaks: After connecting the regulator, carefully inspect all connections for signs of leaks. Apply soapy water to potential leak points and look for bubbles forming. If you detect any leaks, immediately disconnect the regulator and address the issue before using the propane system.

Conclusion

Understanding the unique reverse threading system employed on propane tanks is essential for safe and efficient propane handling. By following the safety precautions outlined in this guide and adhering to proper connection procedures, you can minimize the risk of accidents and ensure reliable performance from your propane appliances. Remember, when it comes to propane, always prioritize safety and consult a qualified professional if you have any doubts or concerns.