A tape dispenser is a ubiquitous tool found in homes, offices, and workshops worldwide. Its simple yet ingenious design streamlines the process of dispensing adhesive tape, making it a must-have for countless tasks, from sealing packages to repairing minor tears. This article delves into the inner workings of a tape dispenser, exploring its key components and functionalities that contribute to its effectiveness.

We’ll begin by examining the fundamental mechanism behind tape dispensing, followed by a detailed look at the cutting blade, pressure plate or lever system, adjustable tension controls, and ergonomic handles. By understanding these elements, you’ll gain a deeper appreciation for the ingenuity behind this everyday tool.

Tape Dispenser Mechanism

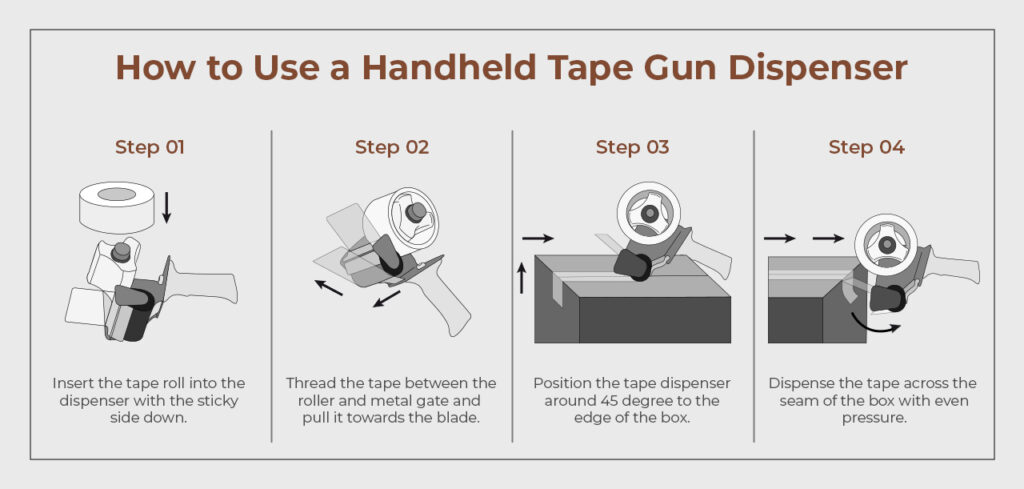

At its core, a tape dispenser operates on a straightforward principle: controlled movement of adhesive tape from a roll to the point of application. This involves several interconnected components working in harmony. The heart of the mechanism is the what’s inside a tape dispenser, which houses the tape roll and facilitates its smooth dispensing.

The base provides stability and support, ensuring the dispenser remains firmly in place during use. A central shaft or spindle rotates to advance the tape from the roll, while guides keep the tape aligned and prevent it from becoming tangled. The mechanism often incorporates a spring-loaded system to maintain tension on the tape, ensuring consistent dispensing.

Cutting Blade Function

A crucial component of any tape dispenser is the cutting blade, responsible for cleanly severing the tape from the roll. These blades are typically made from durable materials like stainless steel or hardened plastic, designed to withstand repeated use and maintain sharpness.

Many dispensers feature retractable blades for safety, allowing them to be retracted when not in use, minimizing the risk of accidental cuts. The blade is positioned strategically within the dispenser mechanism, ensuring it engages with the tape at the desired point for a precise cut. Some dispensers offer adjustable blade positions, enabling users to customize the cutting length based on their needs.

Blade Maintenance

To ensure optimal performance and longevity, regular blade maintenance is essential. Inspecting the blade regularly for dullness or damage is crucial. If necessary, replace the blade with a new one to maintain clean and precise cuts. Avoid using excessive force when dispensing tape, as this can strain the blade and lead to premature wear.

Pressure Plate or Lever System

The pressure plate or lever system plays a vital role in advancing the tape from the roll. This mechanism applies controlled force to move the tape forward, ensuring smooth and consistent dispensing. Pressure plates are typically located beneath the cutting blade, while levers are often positioned on the side or top of the dispenser.

When activated, the pressure plate or lever engages with the tape, pushing it forward along the designated path. The amount of force applied can be adjusted in some dispensers, allowing users to customize the tape dispensing speed and tension. This feature is particularly useful for delicate applications where precise control is required.

Adjustable Tension Controls

Many tape dispensers incorporate adjustable tension controls, enabling users to fine-tune the amount of pressure applied to the tape during dispensing. These controls typically consist of knobs or dials that allow for incremental adjustments.

Higher tension settings provide a firmer grip on the tape, ensuring it doesn’t slip or tear during application. This is beneficial for tasks requiring strong adhesion, such as sealing boxes or packaging fragile items. Lower tension settings are suitable for delicate applications where precise control and minimal pressure are essential.

Ergonomic Handles

Ergonomic handles are increasingly common in modern tape dispensers, prioritizing user comfort and ease of use. These handles are designed with contoured shapes and textured surfaces to provide a secure and comfortable grip.

The placement of the handle is also carefully considered, ensuring it falls naturally within the hand’s reach for effortless operation. Ergonomic handles reduce strain on the wrist and hand during prolonged use, making tape dispensing more comfortable and efficient.

Conclusion

The humble tape dispenser, often overlooked in our daily lives, is a testament to the power of simple yet effective design. Its intricate mechanism, featuring components like the cutting blade, pressure plate or lever system, adjustable tension controls, and ergonomic handles, work seamlessly together to simplify the process of dispensing adhesive tape. Understanding these elements allows us to appreciate the ingenuity behind this everyday tool and its significant contribution to our productivity and convenience.